Building D, Unit D2

Chapel Farm Industrial Estate

Cwmcarn

NP11 7BH

Terms & Conditions | Privacy Policy

Copyright © Spirafix Limited 2026

sales@spirafix.com +44 0345 29 62 792

Spirafix ground anchors are used when a loading needs to be secured for permanent, temporary or semi-permanent applications. The installation and removal is extremely easy, which makes them ideal for all different ground types and provides cost and time savings for prospective projects. Our anchors are used for a multitude of applications, please check out our Projects page or alternatively get in touch with our team to discuss your application.

To understand a bit more regarding installation and removal please see below some points, which will help when using the Spirafix anchor. If you require Spirafix to undertake the installation, please feel free to call our sales team to book our on-site service.

Spirafix ground anchors use the same method of installation and removal whatever the size of anchor, which is impact driven to install and counter rotated to remove. Whenever installing Spirafix anchors please check for buried services prior to install.

Using a sledgehammer or lump hammer, along with a manual hammer cap installation is achieved by impacting the anchor into the ground, we recommend multiple moderate impacts versus heavier larger impacts to allow the anchor to rotate into the ground with each impact.

We would recommend the use of handheld mechanised equipment when installing large anchors or multiple small anchors. When using equipment for the installation of Spirafix anchors it is important to ensure the hammer cap of the machine is perpendicular with the collar of the anchor. This optimises install and preserves the life of the ground anchor.

(Please note an appropriately sized hammer cap must be used with all machinery types.)

| Product code/Equipment name | Power per impact | Anchor suitability |

|---|---|---|

| Electric breakers | 10-15 Joules | 30mm and 40mm anchors |

| Petrol post driver | 25 Joules | 40mm and 50mm anchors |

| Whacker Neuson BH 55 | 55 Joules | 50mm and small 75mm anchors |

| Atlas Copco Cobra driver | 65 Joules | 50mm and small 75mm anchors |

| Atlas Copco Hydraulic driver | 97 Joules | 50mm and 75mm anchors |

These installation methods are generally most applicable when there is a significant number of large anchors to be installed, this can be done using an excavator and adequately sized breaker or by us using the Spirafix piling rig.

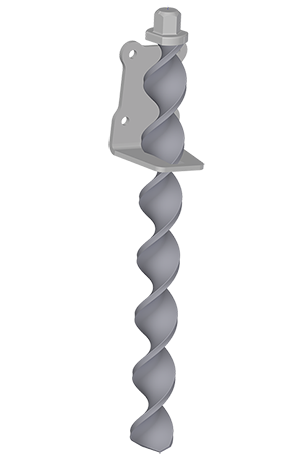

AC type Spirafix ground anchors have internal threaded heads at the top of each anchor this makes them interfaceable with any brackets/baseplates, which have a hole to accommodate for the bolt size. Additionally, we have manufactured a range of brackets which are suitable for the AC type anchors.

For guidance around how Spirafix anchors can be used for bolted applications please don't hesitate t contact our sales team.

| Anchor Size | AC type internal connection |

|---|---|

| 30mm anchors | M10 internal thread |

| 40mm anchors | M12 internal thread |

| 50mm anchors | M16 internal thread |

| 75mm anchors | M24 Internal thread |

C type anchors are suited for through slot bracket applications, this is where the slot has been made to allow the Spirafix anchor to be impact driven through the bracket making an easy hassle-free installation. These are specifically designed for clients ease with no alignment issues to think about and an easy way of fixing the anchors to a bracket. This is best described using pictures which can be seen adjacent.